Benjamin Tubefittings is a reputable manufacturer and supplier of top-notch **Inconel Tube Fittings** located in **Abuja, Nigeria**. With a strong dedication to excellence and precision engineering, this company offers fittings that are built to endure extreme temperatures, high pressures, and corrosive environments. These Inconel fittings are highly regarded across various industrial sectors for their remarkable strength and reliability. Benjamin Tubefittings guarantees superior performance, durability, and compatibility in every product, adhering to global safety and efficiency standards. Their wide array of Inconel Tube Fittings serves industries such as oil and gas, chemical processing, marine, and aerospace applications.

Inconel Tube Fittings are mainly made up of **nickel (over 70%)**, **chromium**, and **iron**, with minor additions of **molybdenum**, **niobium**, and **titanium** to boost strength and corrosion resistance. These fittings boast outstanding mechanical properties, including high tensile strength, excellent creep resistance, and superior oxidation resistance at elevated temperatures. The alloy retains its structural integrity under thermal stress and pressure, making it perfect for demanding operating environments. Inconel Tube Fittings also display impressive toughness, fatigue resistance, and long-lasting performance in both oxidizing and reducing atmospheres.

| Specifications | ASTM B366 / ASME SB366 |

|---|---|

| Size | 1/16 in. to 2 in. & 2mm to 50 mm. |

| Dimensional Range | 1/16 to 2 inches (imperial); 2 to 50 mm (metric) |

| Working Pressures | Upto 2000 to 6000 PSI |

| Thread Type | NPT – ASME B1.20.1, SAE AS71051 | ISO/BSP Parallel – ISO 228 | ISO/BSP Tapered – ISO 7, BS EN 10226-1 | SAE (Unified) – ASME B1.1 |

| End Connections | NPT, ISO/BP, SAE/MS, AN, weld ends, port connectors, sanitary flanges, tube adapters |

| Types | Tube to Union, Tube to Male, Tube to Female, Instrument Pipe Fittings, Accessories |

| Equivalent To | SWAGELOK, PARKER, DK-LOK, HOKE |

| Max Working Pressure | 8MPa | 1200psi Depending on The Tubing Material |

| Working Temperature | -40°C—250°C | -40°F—482°F Depending on The Tubing Material |

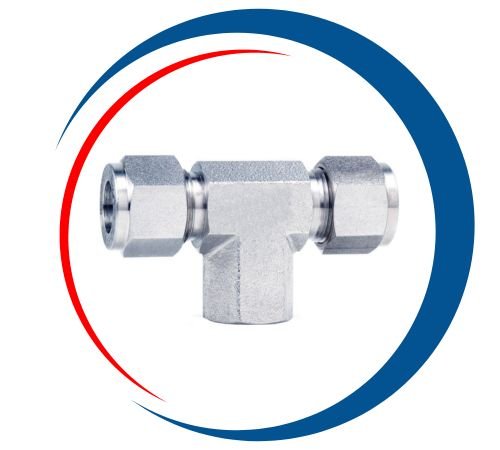

| Configurations | Straights, elbows, tees, crosses, caps, plugs, nuts and ferrules Chromatograph and Column End |

| Tube Fitting uses & application |

|

| Material Test Certificates (MTC) for Tube Fitting as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel Tube Fittings | 0.15 max | 1.00 max | 0.50 max | 0.015 max | 0.50 max | 6.00 – 10.00 | 72.00 min | 14.00 – 17.00 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.47 g/cm3 | 1413 °C (2580 °F) | 655 MPa, 95000 psi | 310 MPa, 45000 psi | 45 % |

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST | OR |

| Inconel Tube Fittings | N06600 | 2.4816 | NC15FE11M | NiCr15Fe | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | ЭИ868 |

Contact us to get a quick quote for your requirement.

Inconel Tube Fittings find extensive use in industries that demand exceptional corrosion resistance and high-temperature performance. They are crucial in the **aerospace**, **marine**, **power generation**, **chemical processing**, and **oil and gas** sectors. These fittings are perfect for connecting pipelines that transport corrosive fluids, acids, and high-pressure gases. Inconel’s stability during thermal cycling makes it an excellent choice for **heat exchangers**, **reactors**, **turbine systems**, and **exhaust manifolds**. Moreover, their non-reactive nature ensures reliability in various applications.

Please feel free to contact us if you need any further information or for enquiry.

©2024 Benjamin Tube Fittings All Rights Reserved.